WHAT IS THE PUREFLOW™ COMPRESSOR?

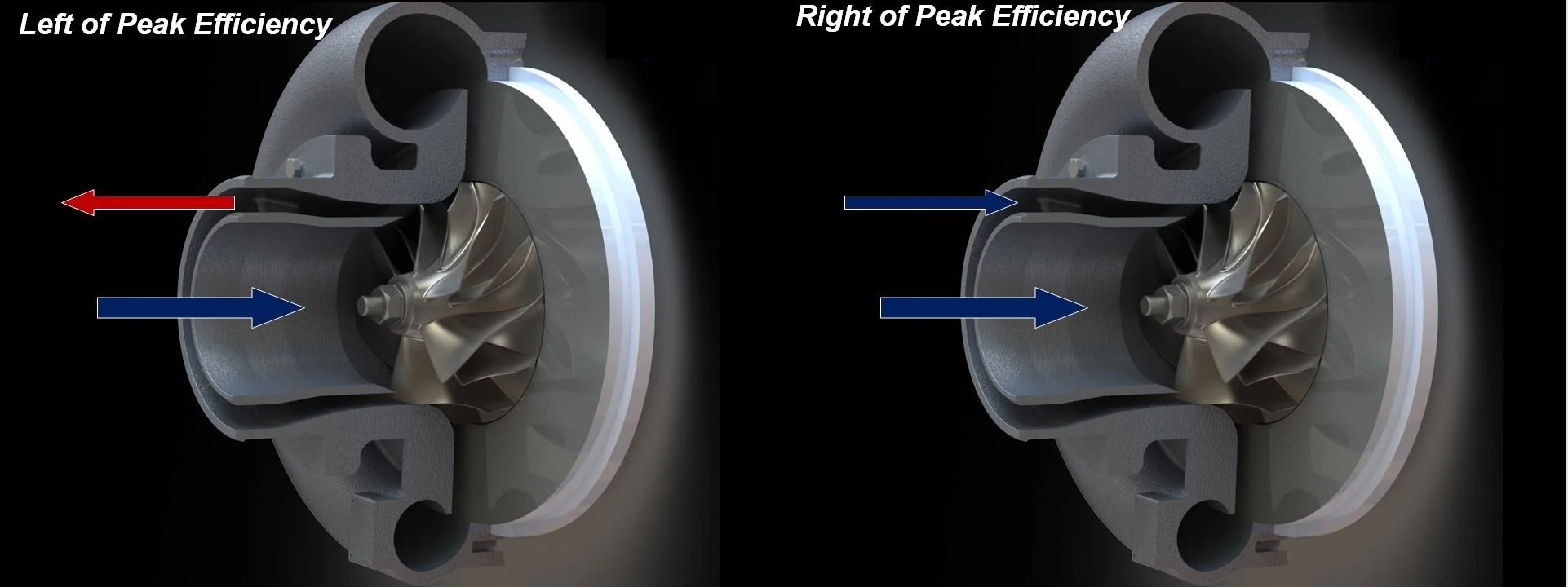

Wide flow compressors regurgitate hot (>125C) air left of peak efficiency which is re-ingested. This significantly reduces efficiency and pressure ratio. It also increases outlet temperature, which increases the turbine work required to drive the compressor. This increases the intake manifold temperature which increases the boost requirement to meet the desired mass flow. You can see the massive increase in temperature below for both a Commercial Vehicle Compressor with ported shroud and a Passenger Vehicle Compressor without a ported shroud.

By simply dividing the inlet piping and air cleaner into two parts, this effect can be eliminated.

The result is a wider map with more boost and more mass flow delivered at a lower temperature to the intercooler at lower engine speeds. This results in quicker transients, more knock resistance for gasoline engines, much more low speed lug torque for a diesel and reduced compressor noise. It will reduce the engine speed where boost kicks in. Best of all, it is independent of the turbocharger and engine manufacturers can implement it separately from their turbo supplier.

I’ll share a little secret with you. Turbo manufacturers have increased the width of the compressor map by changing the CW blade shape, pinched the diffusers and have even put variable geometry inlets or VG diffusers. They all increase map width by increasing the recirculation and tolerance to recirculation. That’s why the efficiencies are down to a ridiculous 50%. If you remove that recirculation, the effect is incredible! Not only does the efficiency increase but the PR jumps—no more flat or negative speed lines. PureFlow™ is superior to inlet guide vanes or variable diffusers and has no moving parts.

HX Version of PureFlow™

A second version retains only one air cleaner and uses a heat exchanger to remove the heat before mixing it back in. To keep the size of the HX small, positive flow can bypass it in the “Auxiliary Positive Flow Path”.

Positive Flow can also go through the HX, but HX keeps the flow small.

A check valve (“reed valve”) prevents reverse flow in Auxiliary path.

Below is an animation of the flow through this configuration of the PureFlow™ near the “old” surge line.